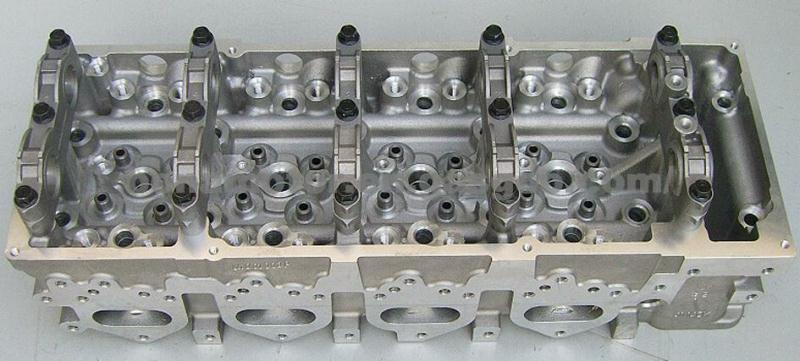

Cylinder Head Reconditioning – Valve Job

ATP Engines uses the latest tooling which enables precise surface finishes and sizing. Our head department is equipped to machine all manufacturers Automotive , Light truck and Industrial cylinder heads. Our capacity is from small heads all the way up to medium range diesel cylinder heads. One of the added benefits of our experience is our in depth knowledge of Import and overhead cam aluminum cylinder heads. Our seat and guide tooling is extensive. We can vacuum test the finished product prior to assembly, a process that ensures quality and saves time.

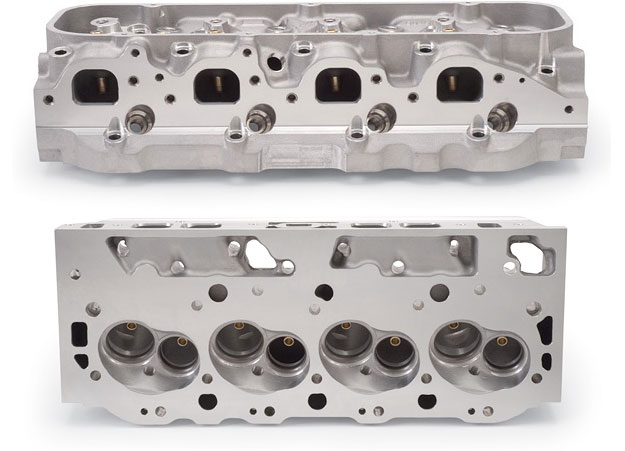

Cylinder Head Resurfacing

ATP Engines utilizes the latest CBN and PCD milling process to produce the required surface finishes for today’s modern gaskets. Our professional machinists are expert in gasket applications and surface finish requirement achieving perfect flatness, surface finish and gasket sealing.

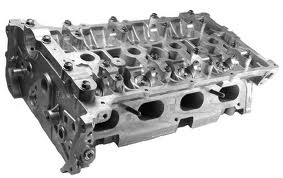

Cylinder Head Pressure Testing

Pressure testing is a must! All Cylinder Heads and Blocks should be pressure tested especially the “Cooked” ones.With today’s modern Multi-Valve Light weight, high output Aluminium Cylinder Heads with Cast Iron Blocks, it has become essential to have a good quality hot and cold Hydraulic Pressure Tester.

The most important criteria to meet is that of: Eliminating Comebacks

The customer must be confident that the “Problem” has been positively identified. Major Piston manufacturers and Cylinder Head Gasket manufacturers that have been consulted have confirmed the need for High Quality Pressure Testing to take place when an engine is reconditioned or remanufactured. With the great difference in Expansion Rates between aluminium, cast iron and modern light weight design, it has become essential to have a High Quality Pressure Test done in order to detect Fractures and Porosity in cores.Tests have proven :that some cores only fracture on disassembly and not when the engine overheats,that some fractures are only evident after a Cold Hydraulic Test, then a Hot Hydraulic Test followed by another Cold Hydraulic Test. It is important to note that these three tests have to be carried out in rapid succession – 10 minutes maximum

Remanufactured Cylinder Heads

ATP Engines utilizes the latest CBN and PCD milling process to produce the required surface finishes for today’s modern gaskets. Our professional machinists are expert in gasket applications and surface finish requirement achieving perfect flatness, surface finish and gasket sealing.

New Cylinder Heads

ATP Engines has over 25 years of experience with Marine Cylinder Heads and high performance engine industry. ATP Marine Cylinder Head division strives to make our customers happy. We produce high quality marine cylinder heads, parts and components. No matter what part you need marine engines , Cylinder Heads and part componants, we stock them all!

We have the best prices for Marine Engines , Marine Cylinder Heads and parts in the industry. We also offer the the lowest domestic and international shipping prices on our marine engines , in the industry. There’s nothing worse than a boat with a dry hull. If you’veexperienced a marine engine failure, we’d like you to consider our Marine Engines , Marine Cylinder Heads and Parts. New or Remanufactured Marine Engines are available from laid back cruising to wide open throttle, ATP Marine Engines provides all the power you need and expect for your boating pleasure. Precision machining and quality parts, combined with thorough testing, give you the highest quality New or Remanufactured Marine Engine around. We have New Marine Engines, Remanufactured Marine Engines, Marine Cylinder Heads and Parts !

Cylinder Head Crack Repair

ATP Engines in shop technicians have built up an extensive range of experience in crack repair utilizing the Irontite pinning method and welding processes. Expert crack repair range from small to large cylinder head, manifold and engine block application. Our In shop team, comprising of highly skilled technicians all with many years experience in mechanical equipment crack repairs will succeed where many others have failed. ATP Engines main focus is to provide accurate reliable crack repairs in shop and on site reducing equipment downtime, and increasing productivity.

ATP Ungines utilizes welding and pinning processes to repair cracks in diesel and automotive cylinder heads and blocks.Once repaired all components are pressure tested to insure the integrity of repair. Our test procedures include dye penetrate, Magnuflux process and pressure testing. Ceramic circulation is also offered.